Revolutionizing the Electric Vehicle Market with VCI: Vapor Corrosion Inhibitors

Welcome to our comprehensive guide on Vapor Corrosion Inhibitors (VCI) and their transformative impact on the Electric Vehicle (EV) market. As the worldwide leaders in Vapor Corrosion Inhibitor Technology, we pride ourselves on providing our customers with comprehensive corrosion management solutions that provide our customers with rust-free results. In this blog, we will explore the

Rust Prevention: How-to Keep Your Metal Parts Rust-Free When Shipping Containers Overseas

Scenario: You’ve recently filled a shipping container and shipped it overseas from North America to Asia. Upon arrival, your customer has complained that rust is rampant throughout the container, and you are planning to ship another container every month. Unfortunately, you can’t afford the rework and scrap costs on the most recent shipments, so what do

Can you use desiccants with VCI?

The short answer is “yes if used correctly.” VCI and desiccants function in different ways in reducing the risk of corrosion. VCI emits a corrosion inhibiting chemistry designed to protect the surface of the metal. Desiccant is designed to absorb atmospheric moisture, reducing the electrolyte that accelerates corrosion. VCI and desiccant do not interfere with each

What to Do When Rust Prevention Fails?

In the manufacturing world, many companies go to great lengths to select products and processes to prevent rust and corrosion from forming on their valuable metal assets during transit and storage. They will probably incorporate volatile corrosion inhibitor (VCI) packaging, rust preventative (RP) coatings, desiccants, or some combination of them. But what happens when their

What Should You Consider When Choosing a VCI Supplier?

Are you in search of a VCI supplier due to company specifications? Currently experiencing corrosion issues at your facility? or just unhappy with the products and services provided by your current VCI supplier? No matter the reason for your search, when choosing a VCI supplier, you should consider this. Is the VCI supplier reputable (ISO

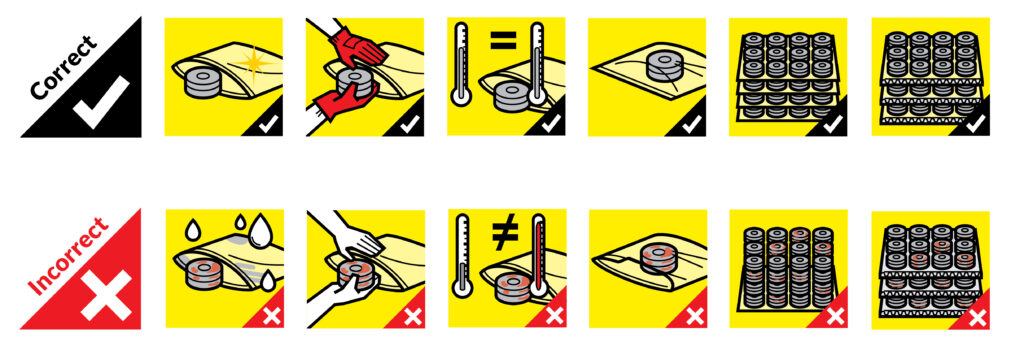

How to use ZERUST® VCI Products Correctly

For nearly 5 decades now, manufacturers and OEMs across the globe have been incorporating ZERUST® Vapor Corrosion Inhibitor (VCI) products into their packaging applications to prevent rust and corrosion during shipping and storage of their metal goods. However, despite years of experience, not everyone fully understands how VCI works and how to use it correctly

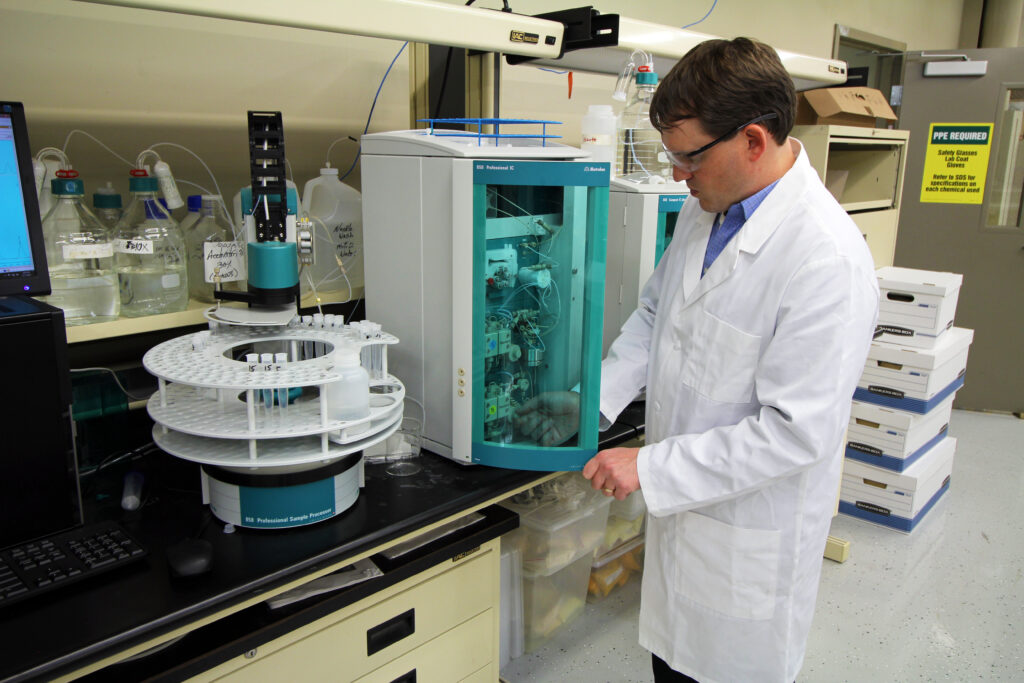

The Various Official Flavors of the Jar Test: Evaluating the Efficacy of Volatile Corrosion Inhibitors (VCI)

The use of anti-corrosive packaging materials functionalized with volatile corrosion inhibitors (VCI) to preserve processed metal parts is critical for any good corrosion management program. Evaluating the efficacy of VCI packaging to provide off-contact protection of steel surfaces is commonly performed in the laboratory using the Vapor-phase Inhibition Ability (VIA) test, also known as the

When VCI Jar Testing Is Not Enough

While the NACE Standard TM0208 Vapor Inhibition Ability (VIA) test, also known as the VCI jar test, is a powerful tool for rapid analysis of VCI packaging and chemistry, it isn’t always robust enough to evaluate the complete protection of VCI packaging. In addition, it is even more limited in its capabilities for testing things