ZERUST® has worked with many companies in various industries over the years. Our sales directors are experts in corrosion solutions for work-in-progress, packaging, shipping, storage, and inventory applications for many industries. We can help you to reduce costs, scrap and rework, and even packaging costs. Our technical team will work alongside you to determine the best corrosion protection packaging for your metal assets.

-

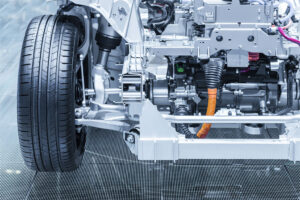

EV Corrosion Solutions for Electric Vehicle Industry

DetailsElectric vehicles (EVs) are becoming an increasingly popular choice for transportation, and it’s not hard to see why. They’re environmentally friendly, cost-effective to operate, and convenient to charge. However, like any vehicle, EVs are subject to corrosion.

-

Heavy-Duty, High-Strength VCI Packaging Solutions for the Metal Coil Industry

DetailsZERUST® has worked with many metal coil suppliers and manufacturers over the years. Our sales directors are experts in corrosion solutions for work-in-progress, packaging, shipping, storage, and inventory applications for metal coils. We can help you to reduce costs, scrap and rework, and even packaging costs. Our technical team will work alongside you to determine the best corrosion protection packaging for your metal coils.

-

VCI Corrosion Solutions for the Heavy Equipment Industry

DetailsZERUST® has been deployed by most major agricultural, mining, and heavy equipment manufacturers and their OEM part suppliers. Our sales directors are experts in corrosion solutions during operation, packaging, shipping, storage, and inventory applications. We can help you reduce costs, scrap, rework, and even packaging costs. Our technical team will work alongside you to determine the best corrosion protection packaging for your equipment.

-

VCI Corrosion Solutions for Metal Stamping and Forming Industry

DetailsZERUST® has worked with many metal stamping and forming companies over the years. Our sales directors are experts in corrosion solutions for work-in-progress, packaging, shipping, storage, and inventory applications for springs, shells, brackets, slides, and other types of stamped metal parts. As a result, we can help you reduce costs, scrap and rework, and even packaging costs. Our technical team will work alongside you to determine the best corrosion protection packaging for your stamped metal parts.

-

ZERUST® VCI Corrosion Solutions for Oil and Gas Industry

DetailsZERUST® has a specialized team dedicated to the oil and gas industry’s corrosion protection needs. As a result, our ZERUST® Oil & Gas VCI technologies have been successfully implemented across refineries, oil rigs, pipelines, and tank farms worldwide.

-

ZERUST® VCI Corrosion Solutions for the Military

DetailsZERUST® VCI military products prevent corrosion in military applications, with many products conforming to Mil specs and having NSN #s. ZERUST® has extensive experience in corrosion prevention and remediation for the military.

-

ZERUST® VCI Solutions for Marine Corrosion Protection

DetailsCorrosion damage is especially prevalent in marine applications, where a constant salt air environment–often combined with high temperature and humidity levels–increases the threat of corrosion. As a result, ZERUST® has extensive experience in Marine corrosion protection in these highly corrosive environments.

-

ZERUST® VCI Solutions for Wastewater Corrosion Protection

DetailsThe corrosion process is incredibly aggressive in wastewater plant environments. ZERUST® field engineers have extensively studied our product’s effectiveness in these situations. The cost and inconvenience of corrosion don’t have to be accepted. Now there is a solution with ZERUST®.

-

Prevent Automotive Corrosion with the use of ZERUST® VCI Products

DetailsZERUST® has been deployed by almost all major automotive companies and their automotive parts suppliers. Our sales directors are experts in corrosion solutions for work-in-progress, packaging, shipping, storage, and inventory applications. We can help you reduce costs, scrap and rework, and even packaging costs. Our technical team will work alongside you to determine the best corrosion protection packaging for your metals.

-

Prevent Foundry & Casting Corrosion with the use of ZERUST® VCI Products

DetailsFoundries around the world have utilized ZERUST® VCI products. Our sales directors are experts in corrosion solutions for work-in-progress, packaging, shipping, storage, and inventory applications. We can help you reduce costs, scrap and rework, and even packaging costs. Our technical team will work alongside you to determine the best corrosion protection packaging for your castings.

-

Prevent Aerospace & Aviation Corrosion with the use of ZERUST® VCI Products

DetailsZERUST® has been deployed by most major aerospace and aviation companies and their OEM part suppliers. Our sales directors are experts in corrosion solutions for work-in-progress, packaging, shipping, storage, and inventory applications. We can help you reduce costs, scrap, rework, and even packaging costs. Our technical team will work alongside you to determine the best corrosion protection packaging for your metals.

-

ZERUST® VCI Music String Envelope Packaging

DetailsMany music string manufacturers use ZERUST® VCI (Vapor Corrosion Inhibitor) envelopes to provide cost-effective and versatile protection against corrosion damage for music strings in shipping, storage, and point-of-sale.