Prevent Foundry & Casting Corrosion with the use of ZERUST® VCI Products

Foundry’s integrity and brand reputation rely upon supplying corrosion-free parts to their customer.

Flash rust is a common issue for foundries due to high humidity at the facility, which is created by metal processing. Without the proper rust-inhibiting method, long-term and short-term storage of cast metal parts can become compromised.

ZERUST® has helped foundries replace oils and solvents using our safe, non-toxic, and environmentally friendly VCI products. Our proprietary Activ™ VCI products are formulated with Vapor Corrosion Inhibitor (VCI) combined with a Volatile Flash Corrosion Inhibitor (FCI™) to protect ferrous metals. This combination goes to work in minutes to protect against both flash rust and long-term corrosion when there are concerns about manufacturing processes and fluids leaving corrosive residues.

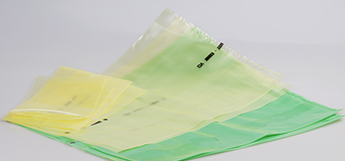

ZERUST® offers a wide array of VCI and corrosion inhibiting products for foundries, ranging from VCI Packaging Films & Paper, VCI Emitters & Diffusers, Rust Removers, Industrial Cleaners & Degreasers, and Rust Inhibitors, Preventatives & Coatings. ZERUST® provides cost-effective and versatile protection against corrosion damage for cast metals in work-in-progress, shipping, and storage.

- VCI Packaging Film & Paper provides effective corrosion protection and packaging combined in one step

- Metals are ready for use and assembly directly out of VCI Packaging Film & Paper

- ZERUST® offers a wide range of rust inhibitor coatings ranging from oil-based, wax-based, water-based, and grease-based to oil additives

- ZERUST® VCI Products provide safe and effective corrosion protection