Who?

What?

Corrosion management for cast parts

Why?

Reduce rust problems on contaminated parts that cannot be oiled

How?

Switched to ZERUST® ActivPak® with ZERUST® VCI Film packaging, eliminating corrosion on rust-prone parts

Corrosion management for cast parts

Reduce rust problems on contaminated parts that cannot be oiled

Switched to ZERUST® ActivPak® with ZERUST® VCI Film packaging, eliminating corrosion on rust-prone parts

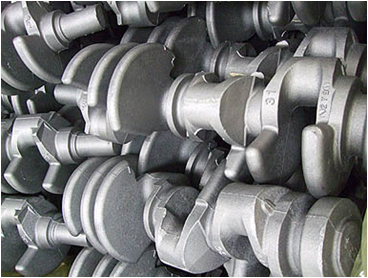

A large US auto manufacturer was plagued by corroded auto parts arriving at assembly facilities. The parts had to be packed hot to add to the challenge, which created condensation. In addition, the manufacturer could not use oils, and the parts had a storage period prior to use. The ZERUST® team of corrosion technicians was invited to diagnose the problem and create a packaging solution.

ZERUST® engineers discovered that contaminants from the casting process were on the parts. ZERUST® recommended using sturdy reusable totes instead of wooden pallets lined with ZERUST® VCI poly bags. To combat contaminants and flash-corrosion, ZERUST® ActivPak® VCI diffuser packets were dispersed throughout the container. This packaging system provided immediate and long-term corrosion protection. The new packaging design solved corrosion issues and significantly reduced costs associated with rework and scrap.

Automotive parts protected from rust & corrosion

2 Years‡

Amount saved

Over $100,000 saved in rework and scrap costs!

Customer Satisfaction

100%

The customer has been delighted with their corrosion-free results and now relies on ZERUST® for all their work-in-process, storage, and shipping VCI needs for their facilities across the US. Contact a ZERUST® Representative for a comprehensive corrosion management solution most effective for your metal assets.