Results

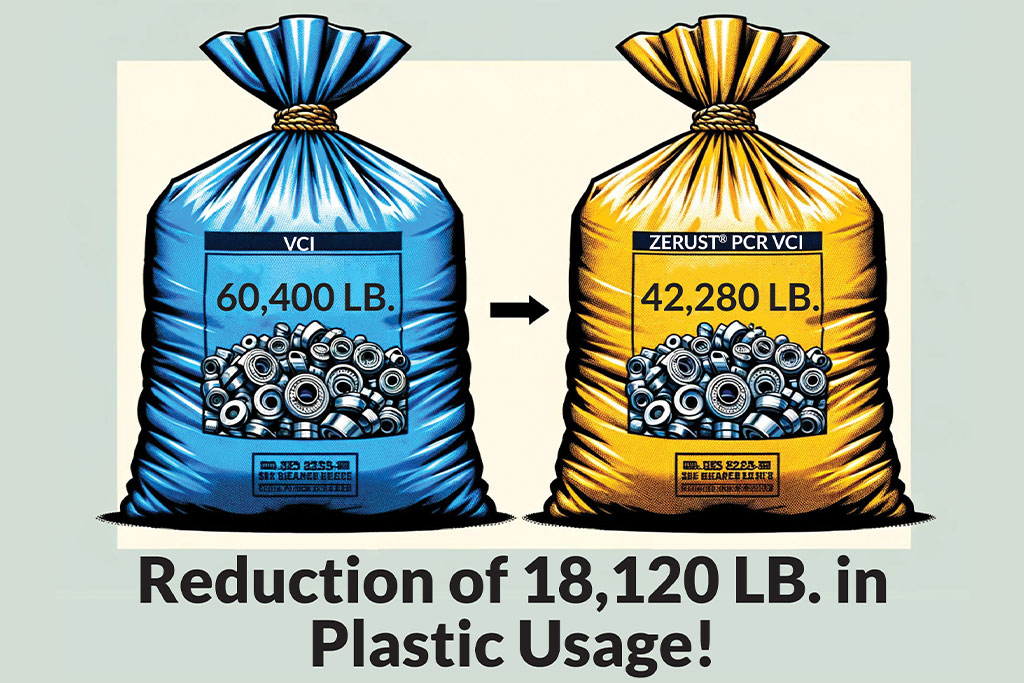

Subsequently, the outcome of this initiative was profound. The manufacturer continued to enjoy the unparalleled ZERUST® difference in corrosion protection while simultaneously benefiting from substantial cost savings, conservation of organic resources, and a marked reduction in waste destined for landfills. This case is a testament to our commitment at ZERUST® to providing superior corrosion protection solutions that prioritize environmental responsibility, setting a new benchmark for sustainability in industrial packaging. Furthermore, through the ZeCycle Recycling Program, ZERUST® offers customers a seamless, closed-loop system to recycle their used VCI products, including ICT®510-PCR30 films and other compatible packaging. The program simplifies recycling by collecting used materials directly from customer facilities, processing them into post-consumer recycled (PCR) pellets, and remanufacturing them into new ZERUST® ICT®510-PCR VCI products.

Carbon Footprint Reduction

Moreover, ZERUST® is reducing the demand for virgin plastics and promoting the circular economy. By choosing ZERUST® products, businesses can protect their metal assets, achieve measurable reductions in their carbon footprint, and make strides in their Zero Waste goals.