In a world where environmental consciousness is on the rise, companies are increasingly seeking innovative ways to reduce their carbon footprint and promote sustainability. One such approach that’s gaining traction is post-consumer recycling, and here at ZERUST®, we’re at the forefront of implementing this technology across our Vapor Corrosion Inhibitor (VCI) polymer packaging solutions. Furthermore, ZERUST® has taken its commitment to sustainability a step further by partnering with RecycleMax® to launch the ZeCycle Recycling Program—a groundbreaking closed-loop recycling initiative that enables customers to recycle used ZERUST® VCI films and plain poly packaging into new ZERUST® ICT®510-PCR film products. With this program, ZERUST® is helping businesses protect their assets, reducing the demand for virgin plastics, promoting a circular economy, and working towards zero waste goals.

In a world where environmental consciousness is on the rise, companies are increasingly seeking innovative ways to reduce their carbon footprint and promote sustainability. One such approach that’s gaining traction is post-consumer recycling, and here at ZERUST®, we’re at the forefront of implementing this technology across our Vapor Corrosion Inhibitor (VCI) polymer packaging solutions. Furthermore, ZERUST® has taken its commitment to sustainability a step further by partnering with RecycleMax® to launch the ZeCycle Recycling Program—a groundbreaking closed-loop recycling initiative that enables customers to recycle used ZERUST® VCI films and plain poly packaging into new ZERUST® ICT®510-PCR film products. With this program, ZERUST® is helping businesses protect their assets, reducing the demand for virgin plastics, promoting a circular economy, and working towards zero waste goals.

Understanding Post-Consumer Recycling

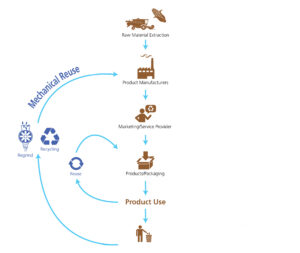

Post-consumer recycling is a process that revolves around the collection, processing (decontamination, washing, sorting), and reuse of materials and products that have been used by consumers and then discarded. This approach is vital for reducing waste, conserving resources, and mitigating the environmental impact of traditional disposal methods like landfills and incineration.

With the ZeCycle Recycling Program, RecycleMax® simplifies this process for customers by managing the collection, transportation, and reprocessing of used VCI films. Customers no longer have to navigate the logistical challenges of recycling on their own. Instead, used VCI packaging is collected from their facilities, processed into post-consumer recycled (PCR) pellets, and remanufactured into new ZERUST® PCR films. This closed-loop system not only diverts waste from landfills but also ensures these materials are reintegrated into a sustainable packaging lifecycle, promoting resource conservation and reducing carbon emissions.

Importance of Post-Consumer Recycling to the Environment:

-

Waste Reduction

Recycling diverts materials from landfills and incinerators, helping to save space and reduce their harmful environmental effects. Landfills can release toxic chemicals and greenhouse gases, while incineration contributes to air pollution. A report from EA Environmental Action (EA) reveals that in 2023, approximately 68.6 million tons of plastic was discarded into the natural environment. This situation arises from a discrepancy between the amount of plastic used and the ability to effectively handle it once it reaches the end of its life cycle. By participating in programs like ZeCycle, companies can address these challenges directly by recycling used VCI packaging into new PCR products, preventing these materials from contributing to global plastic waste.

-

Resource Conservation

Recycling plays a pivotal role in the conservation of our planet’s resources, particularly in the realm of petroleum-based polymer products. By embracing Post-Consumer Recycling (PCR) and participating in programs such as ZeCycle, we can significantly diminish the demand for virgin materials. This is especially critical for products derived from petroleum, a resource that takes millions of years to form. PCR not only aids in reducing our reliance on oil but also mitigates the ecological impact associated with extracting new resources.

Recycling plays a pivotal role in the conservation of our planet’s resources, particularly in the realm of petroleum-based polymer products. By embracing Post-Consumer Recycling (PCR) and participating in programs such as ZeCycle, we can significantly diminish the demand for virgin materials. This is especially critical for products derived from petroleum, a resource that takes millions of years to form. PCR not only aids in reducing our reliance on oil but also mitigates the ecological impact associated with extracting new resources.

-

Energy Savings

The recycling of post-consumer polymers, as seen in the ZeCycle program, is notably energy-efficient, presenting a marked benefit compared to manufacturing new polymers in refineries. This allows businesses to achieve considerable energy conservation while aligning with sustainability goals.

-

Pollution Reduction

PCR and recycling programs like ZeCycle assist with curtailing environmental pollution, offering a greener alternative to the extraction and processing of raw materials. Unlike the practices employed in refineries, which are known to contribute heavily to environmental pollution, PCR operates with a much smaller ecological footprint. By recycling, we actively reduce the pollution of air and water and help in preserving natural ecosystems. This is because PCR avoids the detrimental effects of habitat destruction and soil erosion often associated with the extraction of oil. Emphasizing PCR not only aligns with sustainable practices but also marks a crucial step in diminishing the extensive environmental pollution caused by traditional refining processes, thereby playing a pivotal role in safeguarding our planet’s health.

PCR and recycling programs like ZeCycle assist with curtailing environmental pollution, offering a greener alternative to the extraction and processing of raw materials. Unlike the practices employed in refineries, which are known to contribute heavily to environmental pollution, PCR operates with a much smaller ecological footprint. By recycling, we actively reduce the pollution of air and water and help in preserving natural ecosystems. This is because PCR avoids the detrimental effects of habitat destruction and soil erosion often associated with the extraction of oil. Emphasizing PCR not only aligns with sustainable practices but also marks a crucial step in diminishing the extensive environmental pollution caused by traditional refining processes, thereby playing a pivotal role in safeguarding our planet’s health.

-

Economic Benefits

PCR not only contributes significantly to environmental sustainability but also offers considerable economic advantages. The recycling industry is a growing sector that creates job opportunities, thereby stimulating economic growth. While currently in its nascent stages, as the worldwide infrastructure for recycling expands, we can expect a more pronounced reduction in costs associated with material production and waste processing. This economic benefit, coupled with environmental sustainability, positions PCR as a key driver in both ecological and economic advancement.

-

Conservation of Space

Landfills are limited in capacity, and locating appropriate sites for new ones becomes progressively challenging; PCR and recycling programs like ZeCycle offer a sustainable solution. By redirecting materials away from landfills and into recycling streams, we can significantly extend the lifespan of existing disposal sites. This not only helps in preserving precious land but also safeguards ecosystems that might otherwise be compromised to accommodate waste disposal. The effective management of space through PCR underscores its importance in maintaining ecological balance and highlights its role in the responsible stewardship of our environmental resources.

Landfills are limited in capacity, and locating appropriate sites for new ones becomes progressively challenging; PCR and recycling programs like ZeCycle offer a sustainable solution. By redirecting materials away from landfills and into recycling streams, we can significantly extend the lifespan of existing disposal sites. This not only helps in preserving precious land but also safeguards ecosystems that might otherwise be compromised to accommodate waste disposal. The effective management of space through PCR underscores its importance in maintaining ecological balance and highlights its role in the responsible stewardship of our environmental resources.

-

Circular Economy

Recycling is a cornerstone of the circular economy, where products and materials are designed for reuse and recycling. This approach minimizes waste and resource consumption, promoting sustainability. The ZeCycle Recycling Program exemplifies this circular economy model by creating a closed-loop system for VCI packaging. Starting with the use of ZERUST® VCI films, the program enables customers to collect and recycle their used packaging directly at their facilities. From there, RecycleMax handles the transportation of the materials to specialized recycling facilities, where they are processed into high-quality post-consumer recycled (PCR) pellets. These pellets are then used to manufacture new ZERUST® ICT®510-PCR films, ensuring that materials are repurposed into new products rather than sent to landfills. By participating in the ZeCycle program, businesses actively contribute to the circular economy, reduce their environmental footprint, and align with global sustainability goals.

Challenges with Post-Consumer Recycling (PCR) in VCI Packaging

After collection, sorting the materials is a critical step. The sorting process must be precise to ensure that only suitable materials enter the PCR stream. Contamination with non-recyclable materials or different types of plastics can compromise the quality of the recycled product. However, sorting is labor-intensive and requires advanced technology for accuracy, which can be cost-prohibitive. Additionally, consumer education plays a vital role in this stage; improperly sorted recyclables at the source can significantly hinder the efficiency of this process. Through the ZeCycle Recycling Program, RecycleMax® helps facilities overcome these challenges by providing comprehensive training on best practices for sorting materials. RecycleMax® works closely with customers to educate their teams on how to properly identify and separate recyclable VCI and PE packaging, minimizing contamination and maximizing the value of the materials being recycled. This hands-on approach ensures that materials entering the PCR stream meet quality standards and reduce inefficiencies caused by improper sorting. By equipping facilities with the knowledge and tools they need, the ZeCycle program enables customers to get the most out of their recycling efforts, ultimately improving program success and contributing to a sustainable, closed-loop system.

-

Decontamination

Decontaminating post-consumer materials is essential to ensure they are safe and suitable for reuse in packaging. This process involves removing residues, adhesives, and other contaminants that could affect the quality of the recycled material. Decontamination can be challenging due to the varied nature of contaminants and the need for specialized equipment. It also raises concerns about water usage and handling waste generated from the cleaning process, which must align with sustainable practices. Through the ZeCycle Recycling Program, RecycleMax® addresses these challenges by offering training to facilities on best practices for minimizing contamination at the source. Customers receive guidance on how to properly handle used VCI and LDPE packaging before collection, such as removing excess residue and storing materials in clean, designated areas. This proactive approach reduces the burden on decontamination processes later and ensures that materials entering the recycling stream are in optimal condition for processing. By educating facilities on contamination prevention, the ZeCycle program not only improves the quality of the recycled output but also reduces costs and environmental impact associated with intensive decontamination.

-

Consistency

Achieving consistency in the quality of recycled materials is a significant hurdle. PCR materials often come from diverse sources and have varying histories, leading to inconsistencies in their properties. Maintaining a standard quality in PCR materials is crucial for VCI packaging, which requires specific mechanical and protective characteristics. Manufacturers face the challenge of blending different batches of recycled materials to achieve a consistent product that meets industry standards. This inconsistency can affect the performance of the packaging and its acceptance in the market. Through the ZeCycle Recycling Program, facilities focus on recycling ZERUST® VCI films and other LDPE products with similar properties to ensure uniformity in the raw materials entering the recycling stream. Using RecycleMax®’s network of specialized recycling facilities, ZERUST® closely monitors and qualifies PCR resins to ensure they meet stringent quality standards. These resins are tested and optimized to align with the performance characteristics of virgin ZERUST® VCI products, maintaining the reliable corrosion protection ZERUST® is known for. By controlling the sourcing and processing of PCR materials, the ZeCycle system overcomes the challenge of inconsistency, ensuring that customers receive high-quality recycled VCI products with dependable mechanical and protective performance. This commitment to quality ensures the continued trust and satisfaction of ZERUST® customers while advancing sustainability goals.

-

Performance

Performance criteria such as mechanical properties, purity, and clarity are critical for VCI packaging. PCR materials often fall short in these areas compared to virgin materials. For instance, the mechanical strength and durability may be reduced, affecting the protective capabilities of the packaging. Purity and clarity are also compromised due to the mixture of different types of plastics and the presence of contaminants. Ensuring that PCR materials meet the stringent performance requirements of VCI packaging is a complex challenge. It often requires additional processing steps or the use of additives, which can increase costs and potentially impact the environmental benefits of recycling. ZERUST® addresses these challenges head-on by ensuring that ICT®510-PCR30 products meet the same high-performance standards as ICT®510-C, which is made with virgin resins. Extensive testing in ZERUST®’s labs confirms that the mechanical properties, strength, and durability of ICT®510-PCR30 films are consistent with their virgin resin counterparts, ensuring reliable performance in demanding environments. Additionally, all ZERUST® products, including those made with PCR materials, undergo rigorous quality control to maintain the industry-leading corrosion protection ZERUST® is known for. This ensures that customers can confidently choose sustainable PCR-based VCI products without compromising on quality or protection. The ZeCycle Recycling Program makes this possible by providing high-quality, well-processed PCR resins, aligning sustainability with the uncompromising performance ZERUST® customers rely on.

With the launch of the ZeCycle Recycling Program, ZERUST® has overcome many of the challenges associated with Post-Consumer Recycling (PCR) in VCI packaging. By implementing innovative collection systems, sorting, efficient decontamination processes, and rigorous quality control for PCR materials, ZERUST® has created a seamless and sustainable closed-loop recycling solution. These advancements not only address the common issues often faced in PCR but also ensure that recycled VCI packaging meets the high-performance standards ZERUST® is known for. As a leader in the industry, ZERUST® is paving the way for more effective and sustainable recycling practices, enabling businesses to achieve carbon footprint reductions and make strides in their Zero Waste goals without compromising on quality or protection.

ZERUST®’s Commitment to Sustainability

As a leader in corrosion prevention and rust protection solutions, ZERUST® recognizes the importance of environmental responsibility. Through the ZeCycle Recycling Program, we’ve taken significant steps to address the challenges of post-consumer recycling and promote a circular economy.

VCI polymer packaging is commonly used to protect metal components and equipment from corrosion during storage and transportation. By incorporating post-consumer recycled materials into our VCI polymer packaging products, ZERUST® is reducing the demand for virgin plastics and promoting the circular economy.

ZERUST®’s commitment to sustainability goes beyond recycling. Our VCI polymer packaging solutions not only protect metal products from corrosion but also contribute to a cleaner, greener future by:

- Extending the lifespan of metal assets, reducing the need for replacements, and conserving resources.

- Offering reusable and recyclable packaging options that align with circular economy principles.

- Supporting industries in reducing waste and environmental impact while maintaining the highest corrosion protection standards.

In conclusion, post-consumer recycling is a critical step toward a more sustainable future, and ZERUST® is at the forefront of this movement. Through the ZeCycle Recycling Program, ZERUST® has successfully addressed the challenges of implementing PCR in VCI packaging by creating a seamless, closed-loop system. This program enables customers to recycle their used VCI films into high-quality post-consumer recycled products, reducing their reliance on virgin materials and minimizing their environmental impact. By combining cutting-edge recycling technology with ZERUST®’s trusted corrosion protection solutions, the ZeCycle program empowers businesses to achieve their sustainability goals without compromising on performance. Choosing ZERUST® products means not only protecting your metal assets but also actively participating in the global effort to build a circular economy and a more sustainable future.