As industries worldwide strive for sustainable manufacturing and waste reduction, companies are actively seeking circular economy solutions to minimize their environmental footprint. ZERUST®, in partnership with RecycleMax®, is excited to launch ZeCycle—a revolutionary closed-loop recycling program that transforms used ZERUST® VCI packaging into new post-consumer recycled (PCR) VCI films.

Beyond Recycling: The Second Life of ZERUST® VCI Packaging

Each year, thousands of pounds of polyethylene-based VCI packaging are discarded after protecting metal components during shipping and storage. The ZeCycle Recycling Program closes the loop by enabling companies to efficiently recycle used ZERUST® VCI film and reintegrate it into the supply chain— while maintaining the same high-performance corrosion protection that businesses rely on.

By recycling used ZERUST® VCI packaging into PCR pellets, which are then processed into ZERUST® ICT®510-PCR30 VCI film, businesses can significantly minimize plastic waste while maintaining the same trusted corrosion protection. However, by choosing ZERUST® ICT®510-PCR30 VCI packaging and closing the loop with ZeCycle, companies can take it a step further—reducing their carbon footprint while supporting a circular economy —a true step toward zero waste. Through the ZERUST® and RecycleMax® recycling program, ZeCycle, companies can take measurable steps toward zero waste goals by closing the loop on packaging and incorporating responsible recycling into their operations.

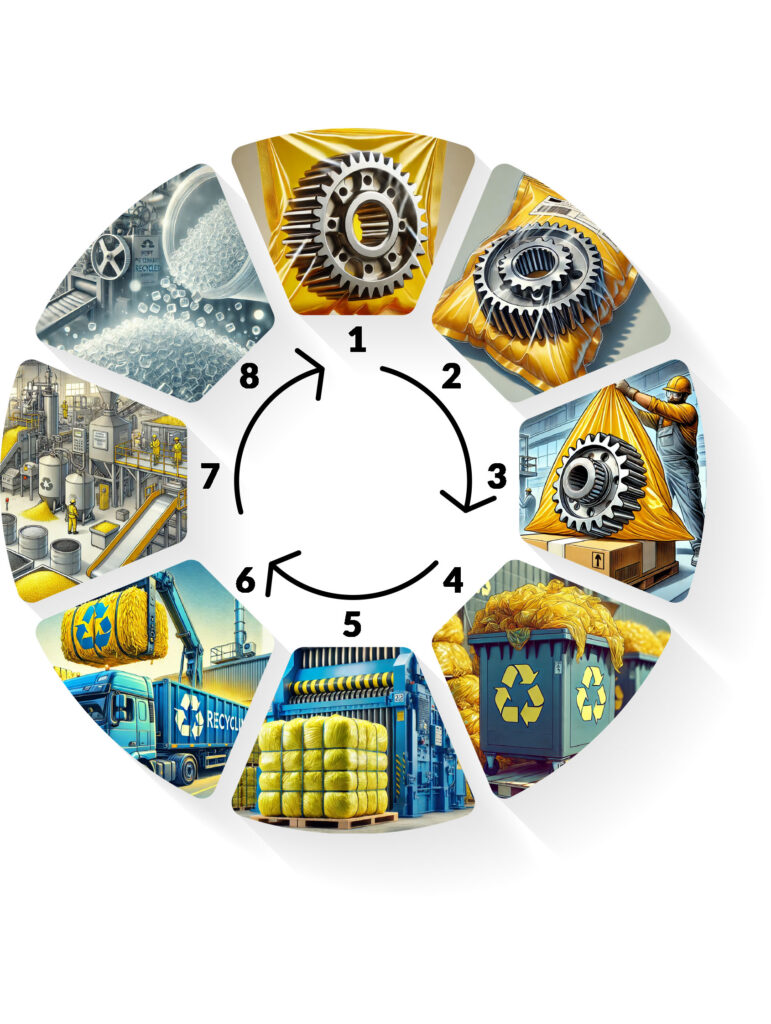

How the ZeCycle Program Works

- Company A packages and ships metal components/equipment in ZERUST® VCI packaging.

- Company B receives metal components/equipment packaged in ZERUST® VCI packaging.

- Company B sorts used ZERUST® VCI and plain poly packaging on-site.

- Company B bales used ZERUST® VCI and plain poly packaging on-site.

- RecycleMax® collects and transports the sorted and baled packaging to a recycling facility.

- Recycled packaging is washed and reground into Post-Consumer Reycled (PCR) pellets at the recycling facility.

- PCR Pellets are used to manufacture new ZERUST® ICT®510-PCR30 VCI packaging.

This end-of-life recovery process ensures that used materials are transformed into new, high-quality ZERUST® VCI packaging, reducing the need for virgin plastics while supporting a circular economy.

Why Choose ZeCycle?

-

Work Towards Zero Waste Goals – Minimize plastic waste by recycling used ZERUST® VCI packaging.

- Lower Carbon Footprint – Reduce emissions by using PCR-based ZERUST® ICT®510-PCR30 instead of virgin LDPE film.

- Simplified Recycling – RecycleMax® manages pickup, transport, and processing while training staff on proper recycling and implementing facility-wide recycling processes.

- Cost Savings – Reduce waste disposal costs through on-site recycling.

- Meet Sustainability Goals – Support a circular economy and regulatory compliance initiatives.

A Measurable Environmental Impact

The ZeCycle Recycling Program provides businesses with a quantifiable sustainability advantage:

The ZeCycle Recycling Program provides businesses with a quantifiable sustainability advantage:

- Carbon Reduction – Every 100,000 lbs of polyethylene film recycled through ZeCycle prevents an estimated 26,000 kg of CO₂ emissions.

- Waste Diversion – Prevents tons of plastic from entering landfills.

- Energy Savings – Using recycled materials significantly reduces energy consumption compared to manufacturing virgin resin.

By choosing ZeCycle, companies take tangible steps toward sustainable practices, reducing both operational waste and their carbon footprint.

Beyond ZeCycle: Achieving Facility-Wide Zero Waste with RecycleMax®

While recycling ZERUST® VCI packaging through ZeCycle helps businesses reduce waste, a comprehensive zero-waste strategy requires a broader approach. Through RecycleMax®, companies can go beyond poly recycling to develop customized zero waste programs—diverting all recyclable materials from landfills and integrating sustainable disposal solutions across their facilities. Partner with RecycleMax® today to maximize waste diversion, reduce costs, and achieve your environmental goals.

While recycling ZERUST® VCI packaging through ZeCycle helps businesses reduce waste, a comprehensive zero-waste strategy requires a broader approach. Through RecycleMax®, companies can go beyond poly recycling to develop customized zero waste programs—diverting all recyclable materials from landfills and integrating sustainable disposal solutions across their facilities. Partner with RecycleMax® today to maximize waste diversion, reduce costs, and achieve your environmental goals.

Explore Waste Solutions with RecycleMax®

Join the ZeCycle Recycling Program Today!

The future of sustainable packaging starts now. Contact your ZERUST® representative today to learn how the ZeCycle Program can help your business reduce waste, lower emissions, and achieve its sustainability goals while maintaining reliable corrosion protection.