ZERUST® Axxanol™ 34CD

ZERUST® Axxanol™ 34CD is a near dry-to-touch light rust preventative coating that leaves a very light, oily film on the protected surface.

Features

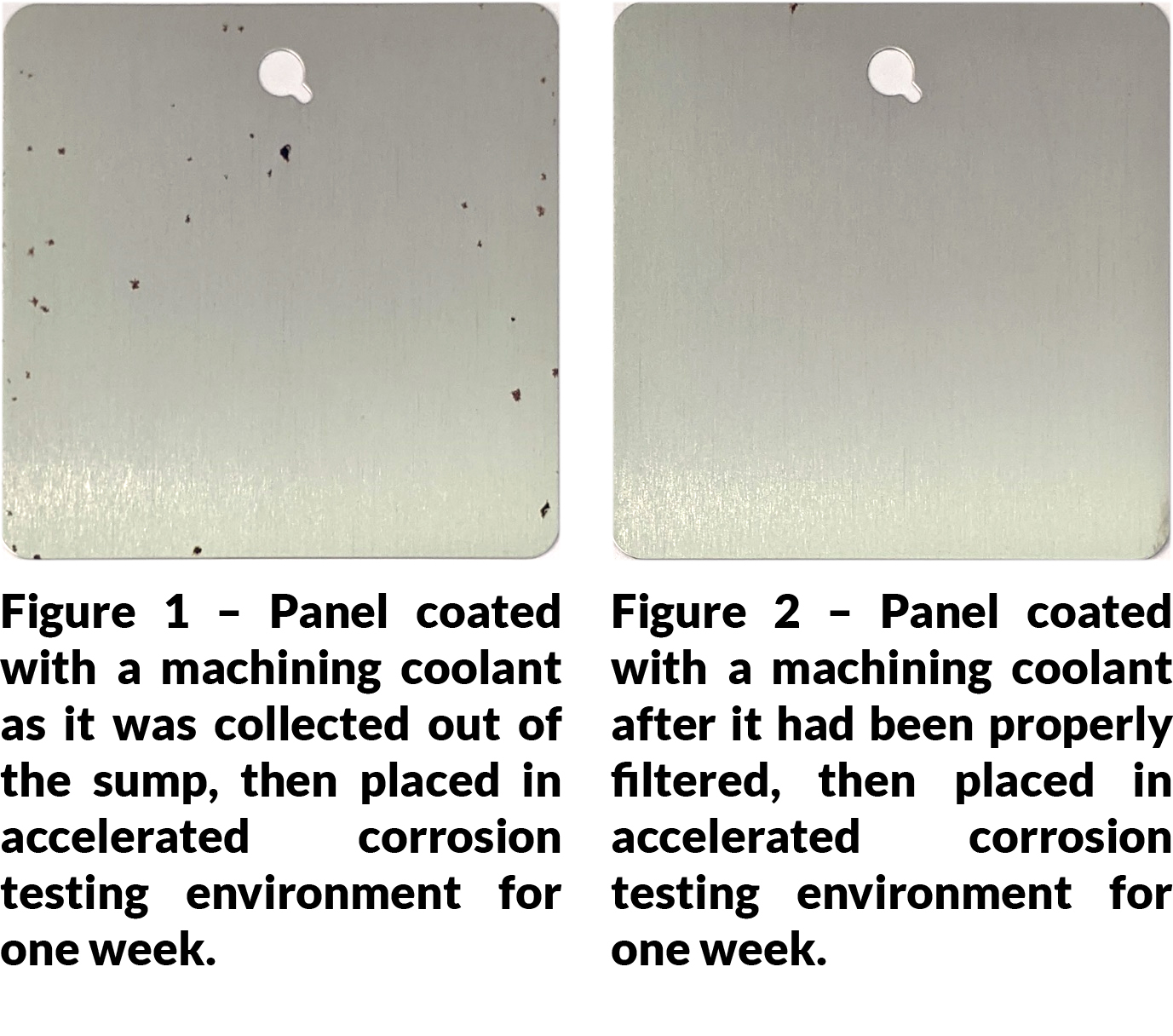

- Proven corrosion protection for challenging environments

- May be used with ZERUST® VCI Film

- Apply by spray, brush, or dip

- Multimetal protection

- Near dry-to-touch light rust preventative coating

- Compatible with most engine oil lubricants

Product Description

Use Axxanol™ 34CD to protect parts during program changeover periods in the assembly process. After allowing metals to dry completely, place them into ZERUST® Vapor Corrosion Inhibitor (VCI) packaging products for a more robust solution that protects for years‡ and during challenging conditions such as ocean shipments. The near dry-to-touch light rust preventative coating can be removed with most alkaline cleaners or left on the surface. In addition, its thin coating does not interfere with torque or pull-out requirements of parts and was tested by an independent lab to be compatible with engine oil.

The Axxanol™ 34CD coated and dried parts are safe to handle and have a near dry-to-touch finish. During drying, the solvent completely evaporates, leaving behind coated parts; you do not need to wear personal protective equipment such as a respirator, mask, or safety glasses. Only clean gloves without lint or talc are recommended to keep metals free of corrosion and contaminants.

Availability

ZERUST® Axxanol™ 34CD is sold as a ready-to-use liquid product.

| Part Number | Quantity | Protection | |

|---|---|---|---|

| 350-M-00012PL | 5 Gallons | Multimetal | |

| 350-M-00012DR | 55 Gallons | Multimetal |