ZERUST® Axxanol™ 750-NV

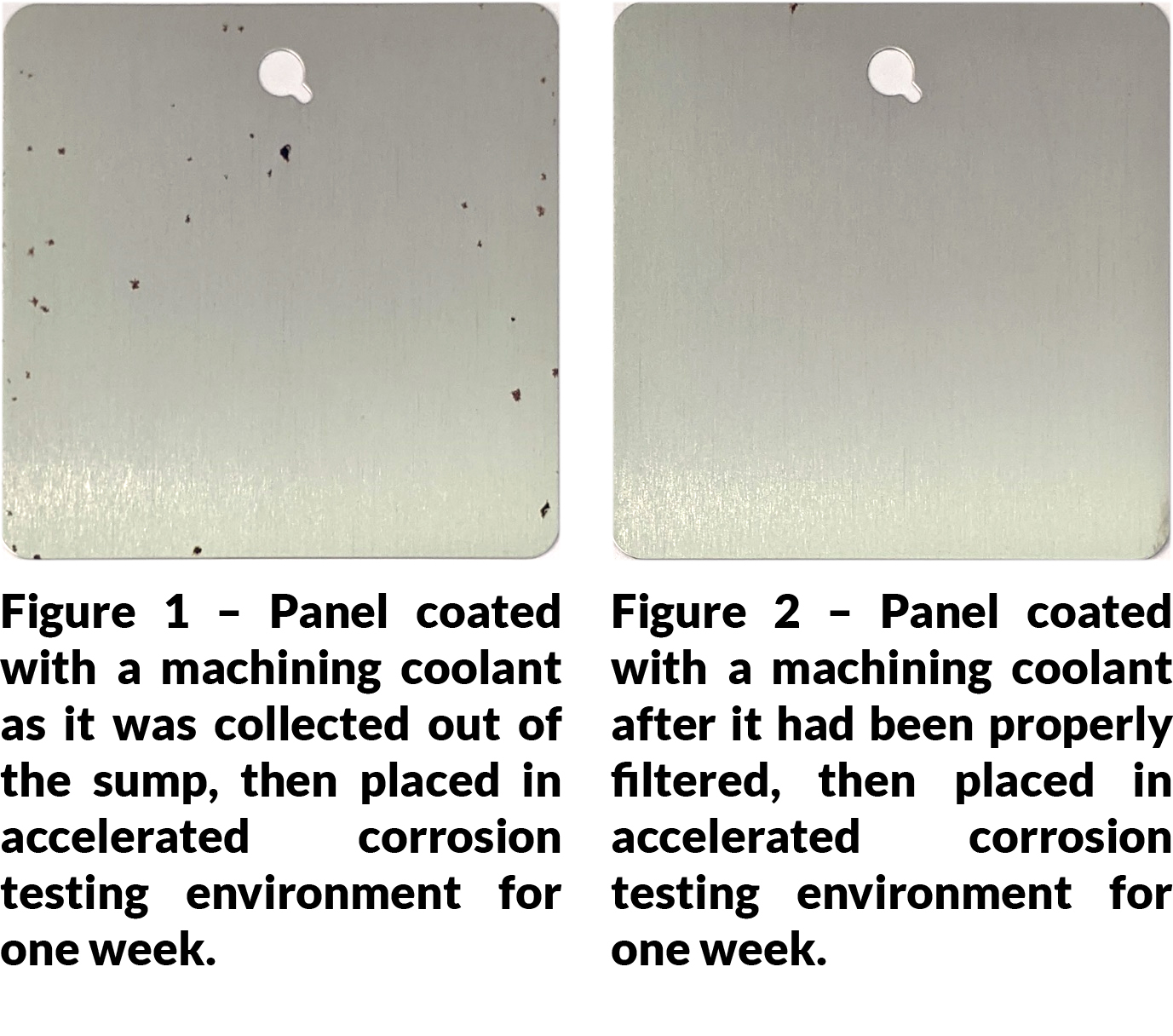

ZERUST®/EXCOR® Axxanol™ 750-NV rust preventive oil provides robust corrosion protection to metal surfaces in an easy-to-use oil-based corrosion preventive coating. It offers corrosion protection for multiple metal types for up to 2 years‡ indoors.

Features

- Advanced ZERUST® corrosion protection technology

- Sprayable and easy to remove

- Multimetal protection

- Non-hazardous*

Product Description

Axxanol™ 750-NV provides powerful corrosion protection against aggressive environments such as salt air and high temperatures for steel, cast iron, aluminum, brass, and copper. It may be used with ZERUST®/EXCOR® ICT® VCI film packaging products for sheltered protection beyond 2 years‡. Apply by spray, brush, or dip.

Axxanol™ 750-NV leaves a clear, thin, oily film that can be removed with an alkaline cleaner. Typical ZERUST® Axxanol™ 750-NV applications include corrosion protection for in-line rolling mill applications, cold-rolled sheets and coils, wire bars, and cast and machined ferrous and non-ferrous metals during shipment and storage. In addition, Axxanol™ 750-NV remains sprayable at sub-zero temperatures of -10°F (-23°C).

Availability

ZERUST® Axxanol™ 750-NV is sold as a ready-to-use liquid product. Large volume quantities and pricing are available upon request.

| Part Number | Quantity | Protection |

|---|---|---|

| 350-M-00033PL | 5 Gallons | Multimetal |

| 350-M-00033DR | 55 Gallons | Multimetal |