Rust can be an ugly sight. But when it comes to the industries that rely on non-corroded metal to run, rust can also lead to some nasty consequences that aren’t always quite so visible: lack of productivity, accidents, and a significant financial loss. Companies are leaching billions of dollars out of their business each year — solely because of corrosion.

Most enterprises don’t understand the true cost of corrosion. But a recent report from NACE International (International Measures of Prevention, Application, and Economics of Corrosion Technology Study) details just how extensive and expensive of a problem corrosion really is.

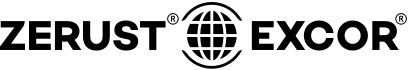

To put it simply, the total cost of corrosion across the globe is astronomical. According to the report, it adds up to an estimated $2.5 trillion (USD), and that number doesn’t even include individual safety or environmental consequences.

That $2.5 trillion sum is nearly 3.4% percent of the global gross domestic product (GDP) — needless to say, corrosion is a massive, costly problem.

In the U.S. specifically, the numbers on corrosion are proportionally similar. For example, the U.S. Federal Highway Administration found that costs directly associated with metallic corrosion added up to $276 billion, or 3.1% of the U.S.’s GDP.

Unfortunately, most organizations don’t fully realize the true impact (financially or otherwise) of corrosion until it’s reached crisis mode. For example, a business could reach a point where the cost to repair materials due to corrosion outweighs the overall profit. Or worse, a company could experience accidents resulting from corrosive equipment.

Given the magnitude of this issue, the purpose of this article is to share information on prevention and control solutions for corrosion. Proactively implementing corrosion controls can save companies significant amounts of money. According to NACE International’s report, it’s estimated that if more used those solutions, the total savings across the globe could be anywhere between $357 and $875 billion (USD) annually. That’s between 15 and 35% of the total cost of corrosion, which is no small feat.

The True Cost of Corrosion

Corrosion makes its impact in various industries—each of which is feeling the financial cost that rust brings. For example, in the U.S., it’s estimated there are 240,000 water main breaks annually, the majority of which are because of corrosion. When corroded pipes fail and water main breaks happen, it’s expensive to replace the pipes. But those breaks also cause water disruptions to homes and schools; cause unscheduled repair work, which can affect transportation and commerce; and the availability of freshwater can be compromised, especially in places affected by drought.

Of course, there’s plenty of piping in the U.S. that’s not carrying water. Instead, pipelines carrying dry gas, wet gas, and crude oil run throughout the country. When corrosion affects those oil and gas pipes, not only is it expensive to replace, but it can also cause expensive disasters if a rusted pipe were to fail.

Even the Department of Defense carries a significant cost of corrosion: a whopping $20 billion. Corrosion impacts the DoD’s planes, vehicles, and other physical infrastructure. So it’s no wonder that within a bureaucracy as large as the DoD, the cost of corrosion is significant.

According to NACE’s report, to stay out ahead of the dangerous and costly consequences of corrosion, it’s actually “mandatory” that organizations implement a Corrosion Management System (or a CMS). So next, we dig further into implementing a CMS.

What is a Corrosion Management System?

According to NACE, a CMS is the “documented set of processes and procedures required for planning, executing, and continually improving the ability of an organization to manage the threat of corrosion for existing and future assets and asset systems.”

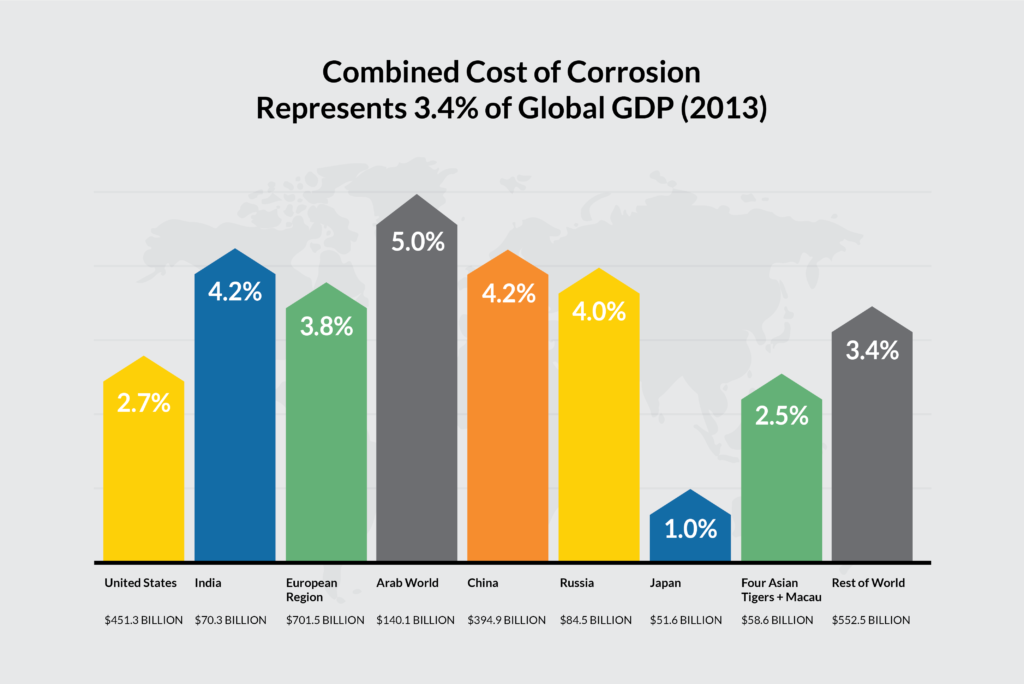

To create a CMS that works for your organization, the key is to balance a solid corrosion technology with a sound management system — combining these two elements gives organizations the efficiency they need to prevent corrosion effectively and, in turn, increase the bottom line.

Within a CMS, there are two management categories:

Management System Elements

- Policy

- Strategy

- Objectives

- Enablers, Controls, and Measures (like Incident Investigation, Documentation, Risk Management, and Communication

- These are the elements that address all threats, even ones not associated with corrosion (which are still essential to have to mitigate corrosion issues)

Corrosion-Specific Elements

- Plans (based on the type of corrosion, ROI, how critical the asset is, its life cycle, and industry regulations)

- Procedures and Working Practices (how to implement, mitigation procedures, and inspection)

All in all, specific corrosion management ideally is a piece that fits naturally into the overall management framework at an organization.

Implementing a Corrosion Management System

The most important part of a CMS is that it needs to be applied throughout an asset’s entire life cycle. So, to be as efficient as possible — and reap the long-term financial benefits of avoiding corrosion—it must be integrated into an asset’s:

- Design

- Manufacturing/construction

- Operation/maintenance

- Abandonment, decommissioning and mothballing (ADM)

Measuring the Business Impact of Corrosion

Lowering the risk of corrosion and proactively controlling it when it does appear can be a valuable focus for countless industries. According to NACE, there are several business impact criteria that organizations can measure when evaluating the cost of corrosion:

- Direct costs (revenue lost)

- People (injuries/fatalities)

- Repair (cost of parts and labor for replacement)

- Major Accident Potential

- Loss of reputation (potential loss of clients or staff; increased borrowing costs; more government oversight)

Corrosion Control is a Business Strategy

Corrosion control is often deprioritized or overlooked in a company because stakeholders aren’t aware of the upside of proactive corrosion control. However, the profits can be significant when corrosion control is implemented well.

“An effective corrosion management program is necessary for successful operations,” Sameer V. Ghalsasi says, a NACE International member. “This process starts as early as the conceptual design phase, and it continues throughout the design life of the facility.”

Corrosion control should be a built-in consideration during the planning phase if a business is in its early stages. Budget and resources should be devoted to corrosion control practices. For existing enterprises, the operations department is the most logical place for corrosion control practices to live. Dedicating projects and even staff members to activating and maintaining corrosion prevention should be ongoing. To emphasize the benefits of corrosion control, read this case study that reflects the power of corrosion control in a business.

Corrosion Prevention: A Success Story

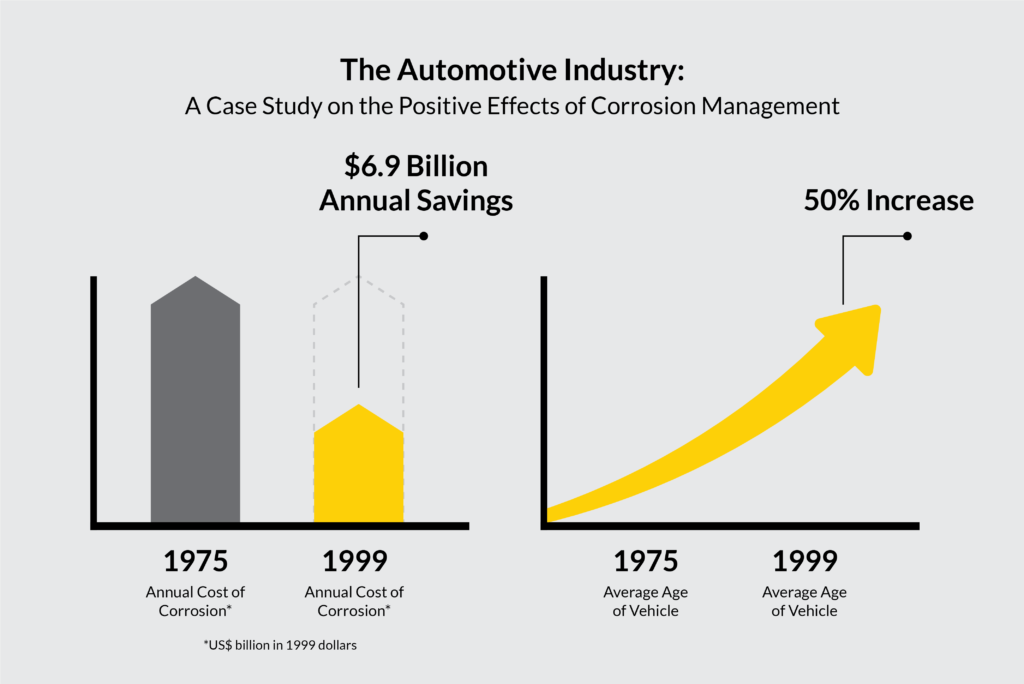

NACE’s report details one of the biggest success stories globally when it comes to corrosion control — the automotive industry. Before 1975, car manufacturers used minimal corrosion control solutions, and it showed. The life cycle of the cars these companies created often depended on the corrosion of the body. And corrosion was costing the auto industry billions of dollars annually.

However, after 1975, the world’s top car manufacturers put a renewed focus on corrosion control, moving forward with advanced painting/coating technology and corrosion-resistant materials.

By 1999, it was estimated that the auto industry was saving $9.6 billion annually. And, perhaps most importantly for both the companies and consumers, the average age of vehicles increased by nearly 50% from 1975 to 1999.

Corrosion, of course, affects countless industries. But the automotive industry is one that recognized early the true cost of corrosion — and the importance of proactively figuring out solutions to control it.

According to NACE, it’s critical that organizations come up with comprehensive Corrosion Management Systems. The cost of industrial rust is enormous, but with CMS in place, it’s estimated that between 15 and 35% of the financial cost of corrosion can be mitigated worldwide. And when we’re talking about numbers that are equal to more than 3% of the worldwide GDP, that’s no small task.

A Future of Corrosion Control

Now that we’ve outlined the clear financial impact of corrosion, it’s essential to focus on a future of corrosion management. This starts at the enterprise level, within operations departments, and through corrosion-specific initiatives. Corrosion management also happens through strategic investment in corrosion control practices and materials.

ZERUST®/EXCOR® offers a complete line of corrosion inhibitor packaging and rust solutions. ZERUST® is the inventor of Volatile Corrosion Inhibitor (VCI) poly technology and offers expert on-site support in over 70 countries worldwide. For nearly 50 years, ZERUST® has helped customers reduce the cost and problems associated with corrosion. Have a challenging corrosion prevention need, such as overseas shipping or storage in corrosive environments? Trust ZERUST® to help you manage corrosion in your operations.