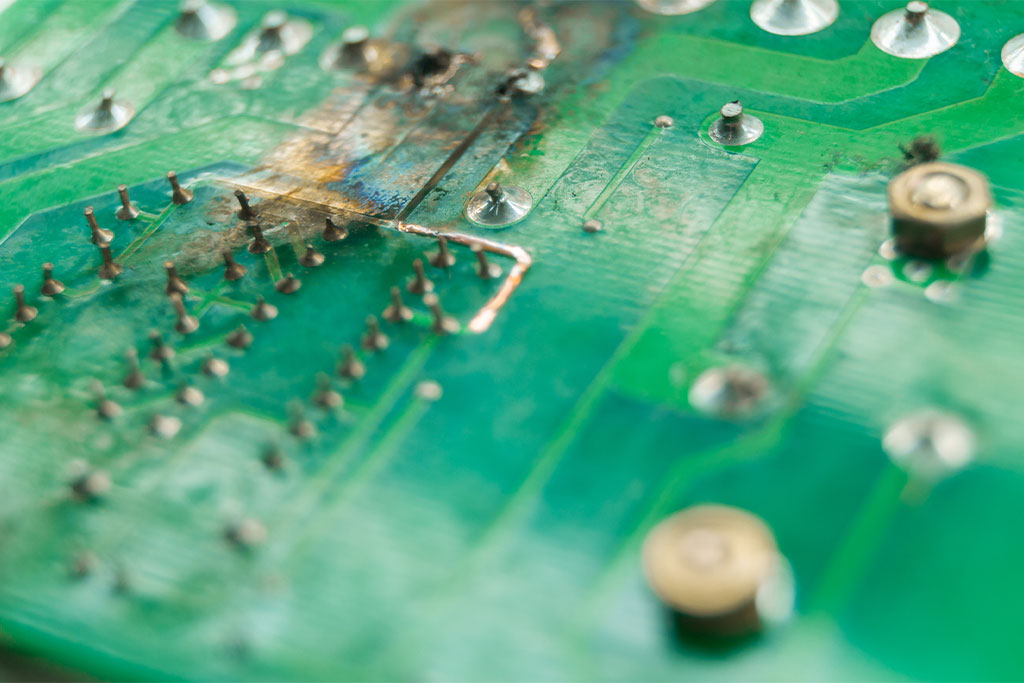

Corrosion protection holds key importance in electrical and electronic applications. Two common approaches for achieving this are conformal coatings (CC) and ZERUST® Axxanol™ 718-ESS, a multimetal electrical corrosion inhibitor spray. In this blog post, we’ll delve into the key differences between these two methods, their respective advantages and disadvantages, and how Axxanol™ 718-ESS stacks up against conformal coatings.

Understanding Conformal Coatings:

Conformal coatings have long been a staple in the electronics industry for protecting circuitry and electronic assemblies from environmental factors like moisture, chemicals, and contaminants. Here are some crucial considerations when assessing conformal coatings:

|

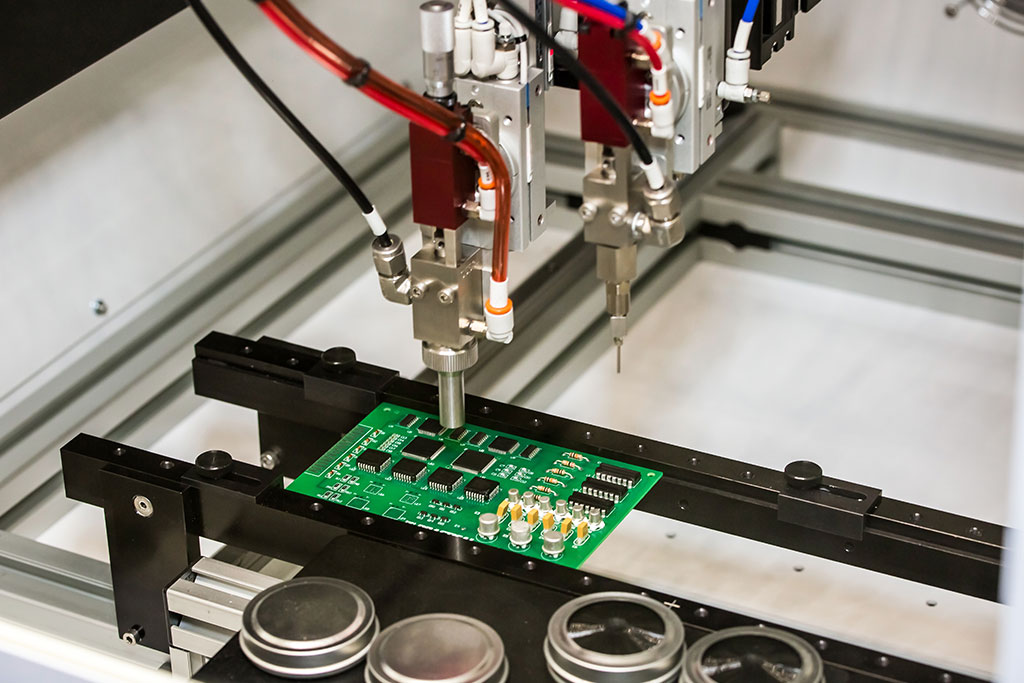

1. Application Methods:

|

|

2. Surface Preparation:

|

|

3. Mechanical Strength:

|

|

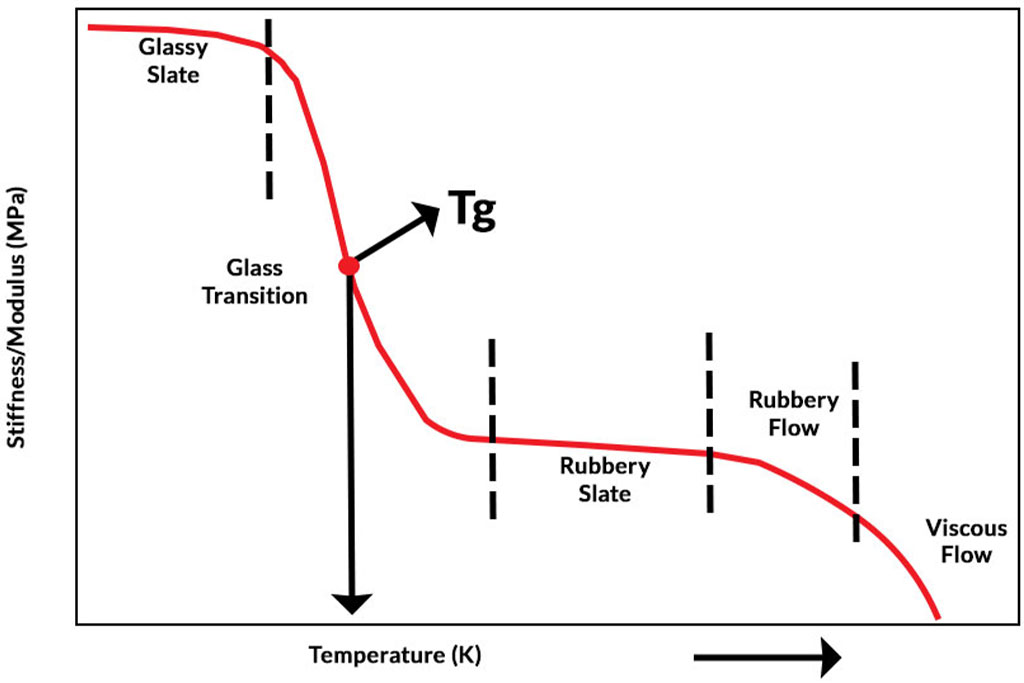

4. Glass Transition Temperature (Tg):

|

|

5. Moisture Permeability:

|

Understanding Axxanol™ 718-ESS:

ZERUST® Axxanol™ 718-ESS presents a different approach to corrosion protection, especially in electrical and electronic applications. Here are the key advantages of Axxanol™ 718-ESS and how it compares to conformal coatings:

|

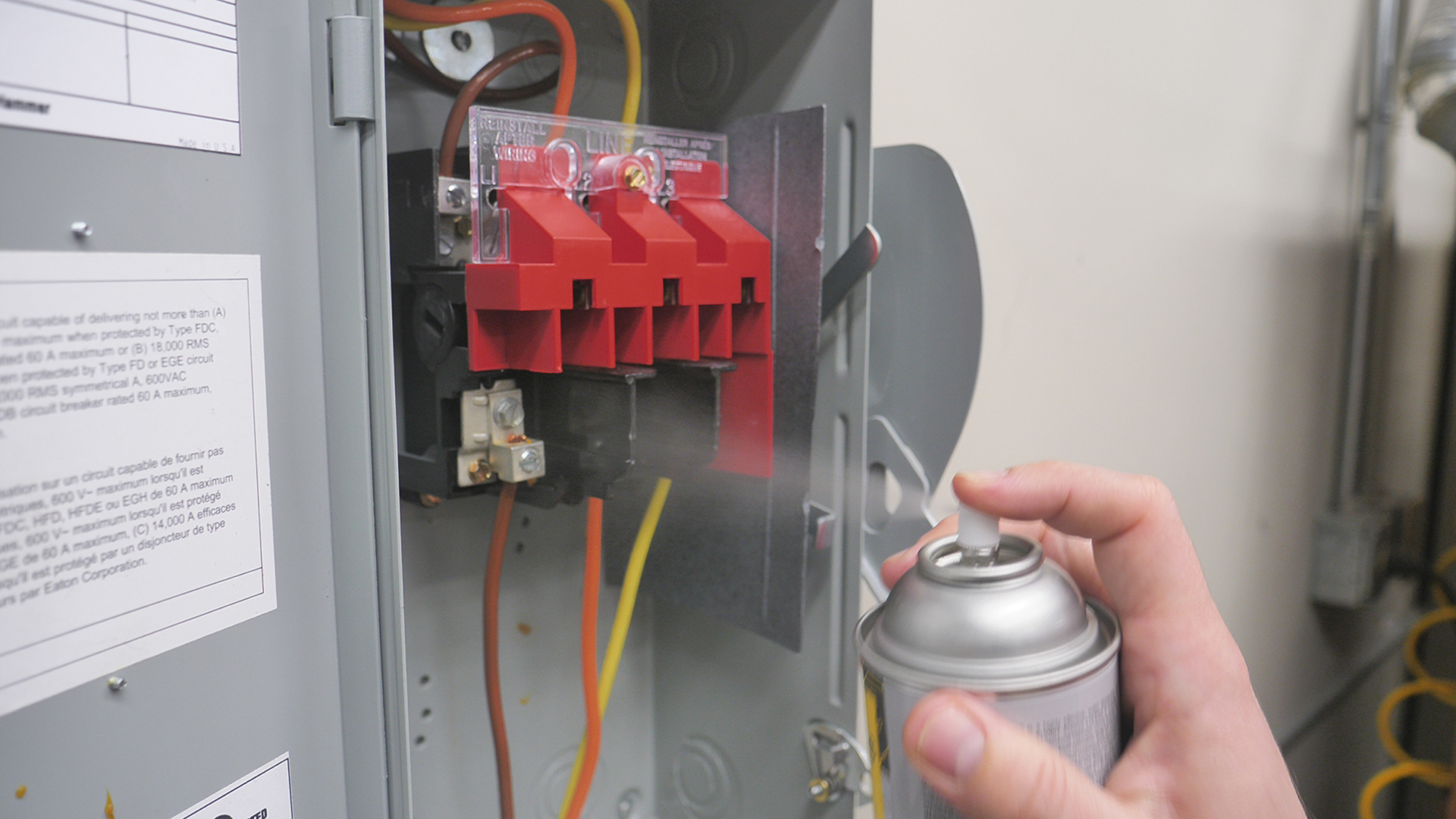

1. Field Application:

|

|

2. Humidity Tolerance:

|

|

3. Stress-Free:

|

|

4. Temporary Protection:

|

|

5. Temperature Limits:

|

Axxanol™ 718-ESS was not designed to compete with conformal coatings but offers unique advantages:

- Axxanol™ 718-ESS is ideal for field application, aftermarket protection, and temporary protection of equipment without the need for conformal coatings.

- Conformal coatings are used for patch repairs of existing coatings facing field failures.

- Axxanol™ 718-ESS is versatile and suitable for various applications beyond electronic corrosion protection.

By understanding these differences and considering your specific needs, you can make an informed decision about whether to choose Axxanol™ 718-ESS or conformal coatings for your corrosion protection requirements. Whether you choose conformal coatings or Axxanol™ 718-ESS, ZERUST® can help you with your corrosion prevention needs. We analyze the current state of your corrosion management needs and work with you and your team to implement the best and most cost-effective solution. ZERUST® can visit your facility and conduct an analysis of your current process. Our mission is to provide you with the right products and procedures to ensure that you can achieve your desired results.