Who?

Brake disc manufacturer in Mexico

What?

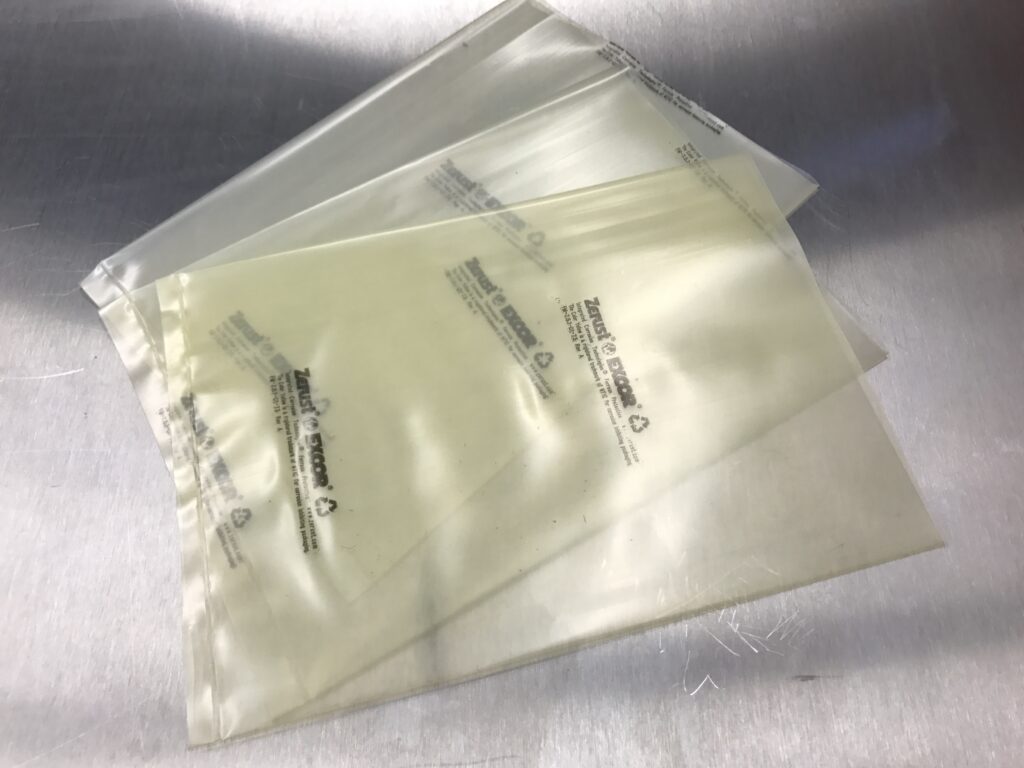

AxxaClean™ 2048 Immersion cleans rusted brake discs and provides flash corrosion protection before coating and ZERUST® ICT® 510-C Ferrous VCI Bags to further protect the brake discs from corrosion during shipping

Why?

The manufacturer requested ZERUST® to complete a process map to identify what was causing the corrosion during the manufacturing process and shipping

How?

ZERUST® analyzed the fluids from the manufacturing line to identify the source of the corrosion and recommend the use of AxxaClean™ 2048 Immersion during the manufacturing process and packaging the finished brake discs in ICT®510-C Ferrous VCI Bags to protection during shipping