Who?

A large automotive parts manufacturer

What?

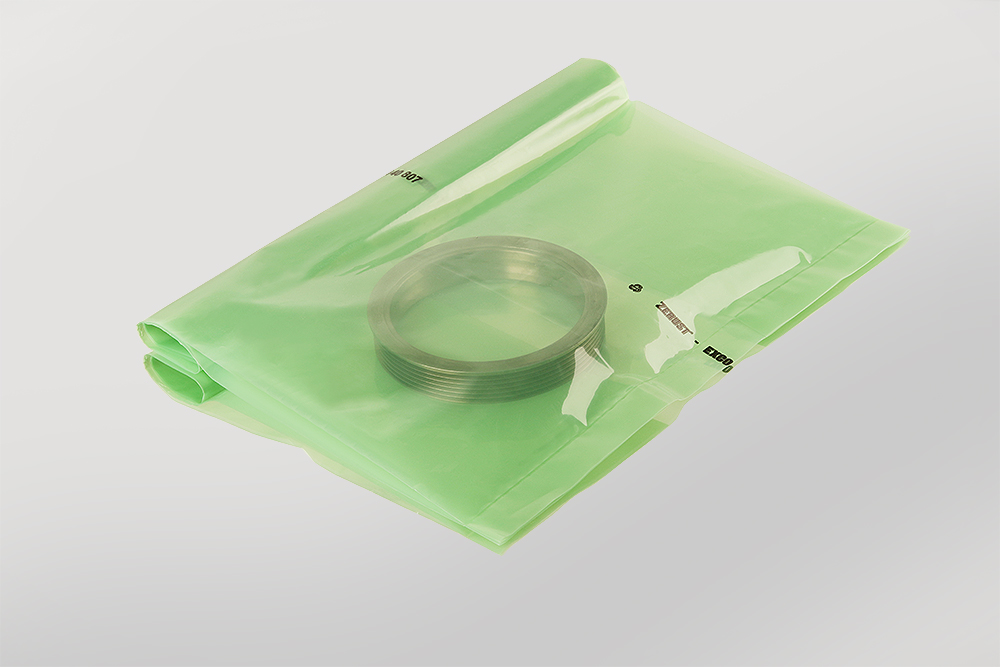

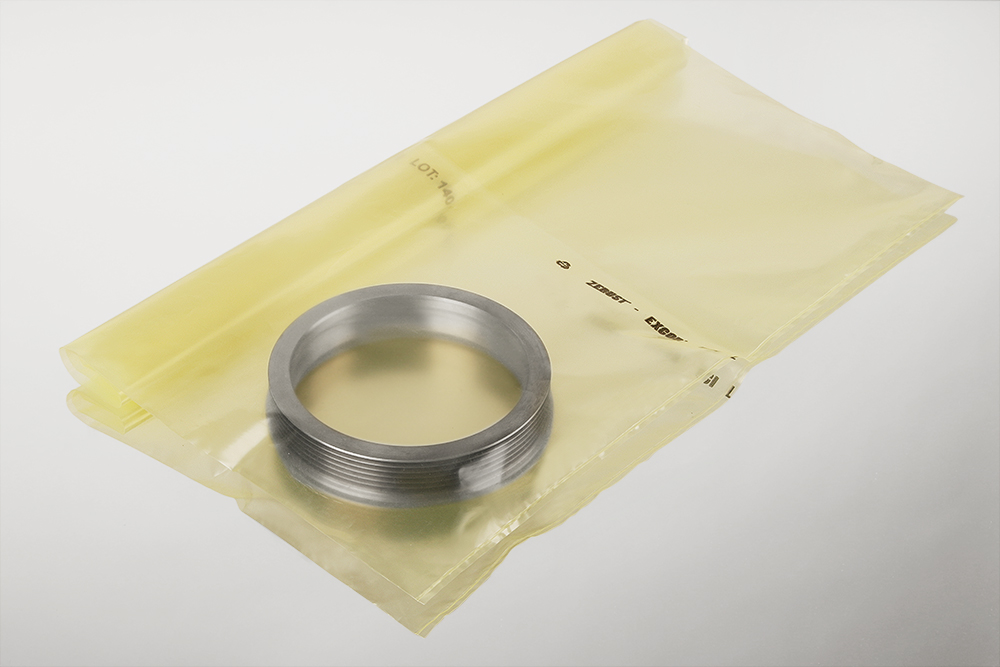

Automotive parts manufacturer was looking to cut down on the number of different VCI bags they needed for their production lines

Why?

Automotive parts manufacturer needed more space on the floor inside of their manufacturing plants and wanted to cut down on the cost of VCI bags

How?

A local ZERUST® representative visited the manufacturing facility to conduct an audit to establish the exact size bag required for each of their totes