Scenario: You’ve recently filled a shipping container and shipped it overseas from North America to Asia. Upon arrival, your customer has complained that rust is rampant throughout the container, and you are planning to ship another container every month. Unfortunately, you can’t afford the rework and scrap costs on the most recent shipments, so what do you do?

Overseas container shipments pose various unique challenges when dealing with metal parts and equipment. From flywheels to industrial machinery, manufacturers are faced with these challenges daily.

Many people realize that shipping containers shipped overseas are exposed to high humidity environments and will include desiccants in their packaging. But unfortunately, desiccant alone is often not enough.

Salt air, day/night dew point cycles (container rain), and compromised containers all put your parts at risk.

To properly plan for container shipments overseas, you need to understand the condition of the metal going into the shipment. This includes the type of metal(s) being shipped, the manufacturing process of the metals (including manufacturing fluids, washes, rinses, etc.), the storage duration and conditions, and the limitations of packaging or defined customer constraints.

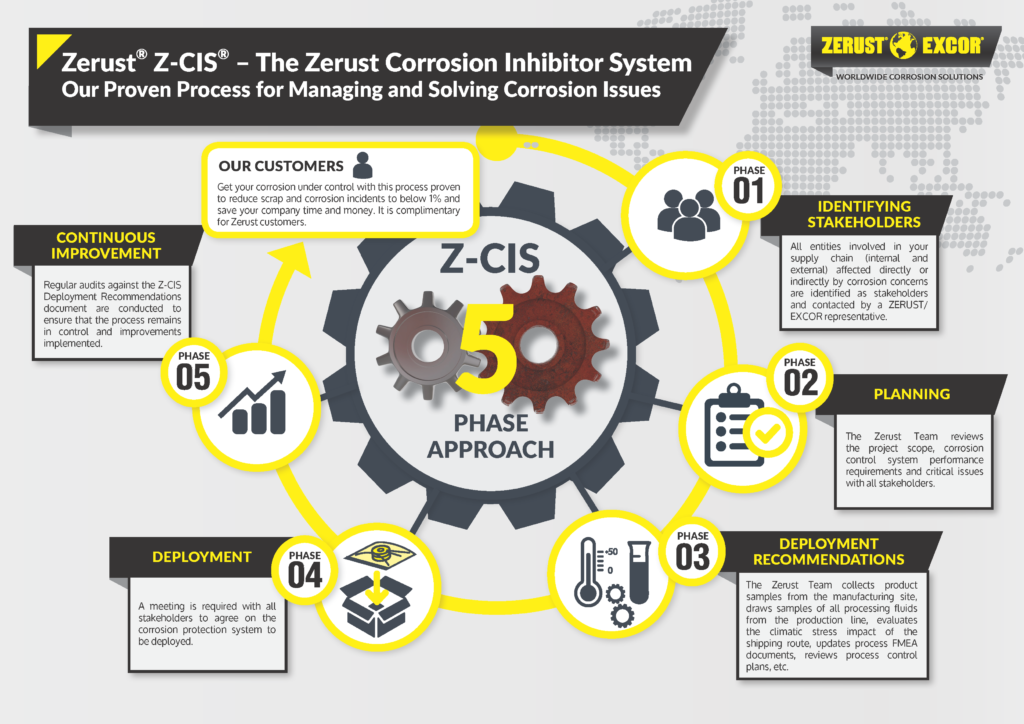

Using the ZERUST® Z-CIS® approach, our rust experts have the skills to design the right packaging solution to protect your parts. Our wide range of contact rust preventative coatings, Volatile Corrosion Inhibitor (VCI) protective packaging, VCI emitters, and desiccants provide the framework to develop a custom packaging solution to fit your needs.

Contact us today for your free corrosion consultation!

ZERUST® can help you with your corrosion prevention needs. We analyze the current state of your corrosion management needs and work with you and your team to implement the best and most cost-effective solution. ZERUST® can come to your facility and do a step-by-step analysis of your current process, including fluid audits, VCI and packaging process audits, and data logger analysis. Our mission is to provide you with the right products, processes, and procedures to ensure that you can achieve your desired results.