Page 3 of 4

Corrosion Considerations Regarding the Concentration Effect in Metalworking Fluids

What is the concentration effect? We have all seen the concentration effect occur in our daily lives. With a kitchen sink full of soapy water used to wash dishes, the more dishes you wash in the water, the dirtier the water gets, and the less effective it becomes at cleaning dishes. As the water in

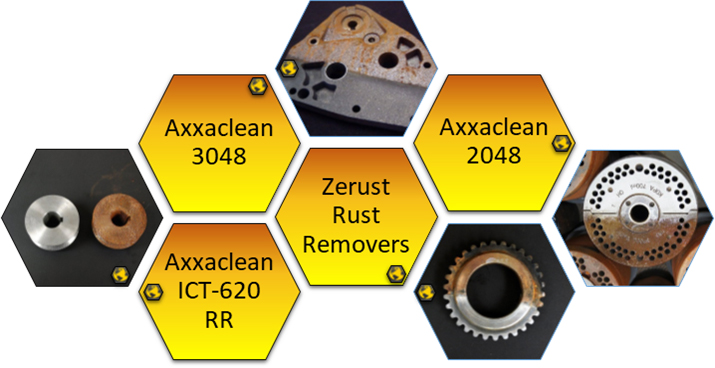

What Is the Best Rust Remover?

Globally, rust is a significant problem. The United States Navy alone calls it a $6 billion problem. The National Association of Corrosion Engineers (NACE) put the cost at 276 billion dollars annually. It affects governments, businesses, and consumers alike. The best approach is to stop rust before it starts using one or multiple approaches such

The Cost of Corrosion

Rust can be an ugly sight. But when it comes to the industries that rely on non-corroded metal to run, rust can also lead to some nasty consequences that aren’t always quite so visible: lack of productivity, accidents, and a significant financial loss. Companies are leaching billions of dollars out of their business each year

Corrosion Solutions for Hydrostatic Testing

Hydrostatic testing of pressure vessels such as pipes, heat exchangers, storage tanks, and ship voids is an essential method for quality control of parts after production and during use. This process demonstrates the fitness of the pressurized component for service after production or repair. Hydrostatic testing consists of raising the pressure level above the operating

Enhance Your Part Cleaning With the Use of ZERUST® Products

Part cleaning is an essential step in the manufacturing process, as precision metal parts typically have oils, greases, and other lubricants on the surface after the part is manufactured. These residues can prevent the adhesion of coatings and paints and accelerate corrosion if not properly removed. Manufacturers understand the importance of delivering clean parts in

ZERUST® VCI Film Additives & Custom Options

ZERUST®/EXCOR® (Vapor or Volatile Corrosion Inhibitor) VCI film, poly bags, and tubing are produced using a process known as blown film extrusion. The polyethylene is melted and extruded into sheeting which is then slit, folded, or sealed to the desired size and dimensions. With ZERUST’s vast manufacturing network, we have over 100 extrusion lines in

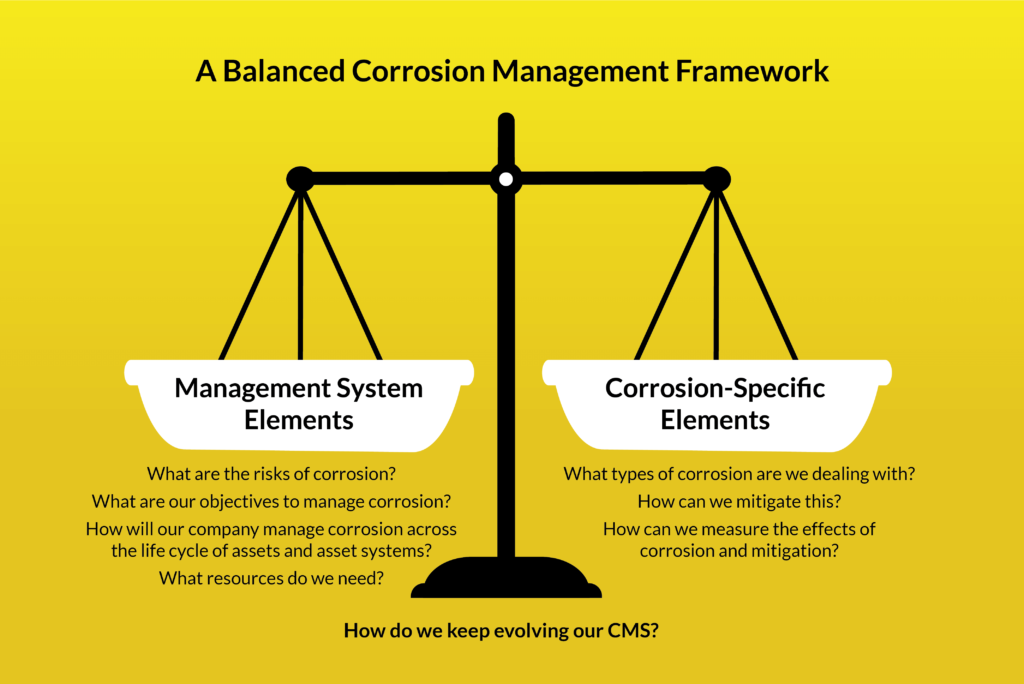

6 Straight Forward Steps to Get Rust Under Control

Opening up a container to discover corrosion on metal items is frustrating. It often means lost time, missed deadlines, and unhappy people in your supply chain. The loss or rework of the corroded items plus the impact on business all total up to a significant cost. Corrosion can be complicated and may be caused by

5 Best Practices for VCI Packaging Storage

Do you currently use Volatile Corrosion Inhibitor (VCI) packaging to protect metals from corrosion? Are you wondering about the best way to store VCI packaging, such as rolls of poly sheeting and VCI gusset bags, before use? Since VCI products are designed to diffuse their protective chemistry into open spaces, the key to preserving their effectiveness

RP Oils or VCIs: Which Protection Method is Best for Me?

When considering corrosion protection methods, plenty of options are available. The two methods most used for protecting metals during the manufacturing processes of shipment and storage are corrosion inhibitor liquids and VCI (volatile corrosion inhibitor) packaging products. Corrosion inhibitor liquids, also known as “Rust Preventatives” (RPs) or oils, are available in a wide range of

Is There a Rust Season or is it Open Season for Rust?

When you mention the words “rust season” to someone in the metalworking industry, you may get a dry smile. Their immediate answer is typically summer, when high heat and humidity create the perfect conditions for corrosion. Unfortunately, that answer is usually quickly followed by reasons why their metals can corrode the rest of the year.