ZERUST® is the original VCI film company that invented VCI-infused plastic technology. ZERUST® VCI packaging films are available in many stock and custom options. VCI Film comes in a range of sizes and MIL thicknesses and can be made in VCI plastic sheets, tubing, J-sheeting, and c-fold sheeting. Some stock bag options are flat VCI bags, zipper bags, and VCI gusset liners. In addition, a range of metal protection types are available, as well as acid-gas scavenging technology and additives such as ESD and UV protection can be incorporated. Valeno® VCI film is a registered trademark of Excor®.

ZERUST® ICT®510-C VCI Film

Use ICT®510-C VCI Film for cost-effective and versatile protection against corrosion damage for metals in shipping and storage.

ZERUST® ICT®510-PCR30 Post-Consumer Recycled (PCR) VCI Film

ICT®510-PCR30 Post-Consumer Recycled (PCR) VCI Film is a 30% recycled polyethylene film containing proven ZERUST® Vapor Corrosion Inhibitors (VCI), providing cost-effective and versatile protection against corrosion damage for metals in shipping and storage.

ZERUST® ICT®510-C Ferrous VCI Film

Use ICT®510-C VCI Film for cost-effective and versatile protection against corrosion damage for ferrous metals in shipping and storage.

ZERUST® ICT®510-C Non-Ferrous VCI Film

Use ICT®510-C Non-ferrous VCI Film for cost-effective and versatile protection against corrosion damage for non-ferrous metals such as aluminum, copper, brass, bronze, and galvanized steel in shipping and storage.

ZERUST® ICT®510-C Multimetal VCI Film

Use ICT®510-C VCI Multimetal Film for cost-effective and versatile protection against corrosion damage for ferrous and non-ferrous metals in shipping and storage.

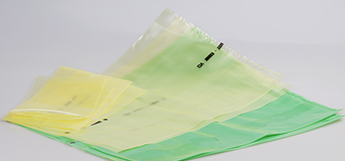

ZERUST® ICT® VCI Bags

ZERUST® VCI Poly Bags diffuse Vapor Corrosion Inhibitors to protect metal components, machined parts, engines, molds, and more from rust and corrosion.

ZERUST® ICT®510-C VCI Tubing

Use ICT®510-C VCI Tubing for cost-effective and versatile protection against corrosion damage for metals in shipping and storage.

ZERUST® ICT®510C-AN VCI Film Series

ICT®510C-AN VCI packaging film series are nitrite-free and non-amine formulated products. They are ideal for the protection of metals in corrosive environments or for metal types susceptible to flash corrosion.

ZERUST® Natur-VCI® Film

ZERUST® Natur-VCI® film is engineered for safe disposal in a professionally managed composting facility, where the carbon in the film is utilized as a food source by micro-organisms to completely break down the plastic into humus, water, and CO2.

ZERUST® ICT®520-CB1 Anti-Tarnish VCI Film

Use ICT®520-CB1 Anti-Tarnish film to protect silver, copper, bronze, brass, or tin from unsightly and damaging oxidation and tarnish.

ZERUST® ICT®520-CSL Cold Seal VCI Film

Use ICT®520-CSL Film to save valuable time, equipment, and labor in packaging operations by eliminating the need to heat-seal, apply tape, or staples.

ZERUST® ICT®510-CLHD High Density VCI Film

Use ICT®510-CLHD high-density film for interleaving purposes, to laminate other materials or as a replacement for VCI kraft paper during shipment, storage or work in progress.

ZERUST® ICT®520-HS High-Strength VCI Film

ICT®520-HS High-Strength VCI film is less likely to puncture or tear compared with traditional polyethylene film, so it is especially suited for applications that have demanding corrosion protection requirements.

ZERUST® ICT®510-MSF VCI Masking Film

ICT®510-MSF VCI Masking Film is a pressure-sensitive adhesive film. It provides protection from scratches and dust as well as corrosion. In addition, the film removes cleanly and does not leave a residue.

ZERUST® ICT®504-LM Moisture-Limiting VCI Film

ICT®504-LM Film provides significantly elevated corrosion protection for iron and steel while dramatically lowering the Water Vapor Transmission Rate (WVTR) of the package (30% reduction on average).

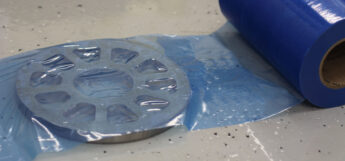

ZERUST® ICT®510-OPS Outdoor Preservation VCI Shrink Film

Use ICT®510-OPS VCI Shrink Film for long-term outdoor storage and mothballing of parts and equipment. ZERUST® film protects valuable assets from corrosion when stored outdoors and enables items to be stored near the project site and be operationally ready.

ZERUST® ICT®510-SRK VCI Shrink Film

ICT®510-SRK Film is polyethylene shrink film impregnated with Vapor Corrosion Inhibitors that shrinks tightly around the item when subjected to heat, providing a contoured fit and VCI protection.

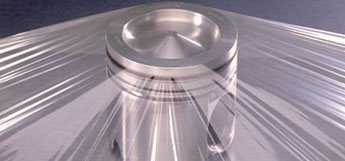

ZERUST® ICT®510-SK Skin VCI Film

ZERUST®/EXCOR® ICT®510-SK VCI Skin Film is a polyethylene skin film containing Vapor Corrosion Inhibitors to provide superior corrosion protection to fragile items during shipment and storage.

ZERUST® ICT®540-SDA VCI Film

ZERUST®/EXCOR® ICT®540-SDA Advanced VCI Film is a premium corrosion-inhibiting packaging product for use in extreme long-term storage and challenging conditions. When properly packed and sealed, it protects metals in contaminated acid gas and marine environments.

ZERUST® ICT®510-SM VCI Stretch Film

Use ICT®510-SM VCI Stretch Film to wrap and protect metal items from corrosion and damage in storage and shipping.

ZERUST® ICT® Poly VCI Weapon Bags

Use ICT® VCI Weapon Bags to provide protection against corrosion damage for weapons and accessories in shipping, storage and in-between operations.

ZERUST® ICT® VCI Tote Covers

Use ICT® Tote Covers to protect metal parts from both contamination and corrosion while in temporary storage.

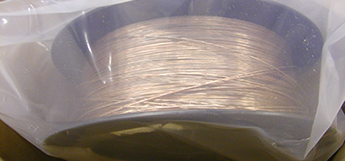

ZERUST® ICT® VCI Coil Covers

ICT® VCI Coil Covers are custom products designed to cover the most common sizes of metal coils and act as a barrier of protection against dirt, dust, smoke, and other contaminants.

ZERUST® ICT®570 VCI Foam Sheeting

Use ICT®570 VCI Foam Sheeting for lightweight and resilient packaging material that prevents rust using Vapor Corrosion Inhibitors.

ZERUST® ICT®520-SRA VCI Plastic Scrim

ICT®520-SRA Scrim VCI Film is a durable polyethylene fabric film with woven strands for strength and tear resistance, preventing corrosion and damage in shipping and storage.

ZERUST® ICT® VCI Profile Board

Use ZERUST® Profile Board in place of traditional corrugated sheeting to provide strength and corrosion-inhibiting capability.

ZERUST® ICT®520-XF VCI Film

ICT®520-XF is an opaque black VCI film that offers superior corrosion protection for heavy, large, or irregularly shaped items.

What is VCI Packaging Film?

VCI Packaging, or Vapor Corrosion Inhibitor packaging film, is a poly packaging film manufactured with added VCI chemistry. VCI molecules protect metals from corrosion by forming a thin, invisible layer on the surface.

This layer inhibits the corrosion process caused by oxygen, water, and contaminants. Vapor Corrosion Inhibitor packaging can be made in different sizes, weights, and inhibitor types. In addition, it can be ordered in rolls, bags, and with custom printing.

How Does VCI Packaging Film Work?

VCI Packaging, or Vapor Corrosion Inhibitor packaging film, emits molecules that settle on metal surfaces and form an invisible layer that protects from corrosion. It protects by interrupting the electrochemical corrosion process caused by moisture, oxygen, and contaminants in the atmosphere.