Articles by Tom White

Page 2 of 2

5 Reasons the Steel Coil Industry Prefers VCI Paper and Poly for Optimal Steel Coil Corrosion Protection

Corrosion is a significant challenge in the steel coil industry, causing damage to steel coils and resulting in decreased productivity and profitability. As a result, rust-preventative coatings have commonly been used by steel coil suppliers and manufacturers to provide steel coil corrosion protection during storage and transportation. However, one solution in the steel coil industry has

What Should You Consider When Choosing a VCI Supplier?

Are you in search of a VCI supplier due to company specifications? Currently experiencing corrosion issues at your facility? or just unhappy with the products and services provided by your current VCI supplier? No matter the reason for your search, when choosing a VCI supplier, you should consider this. Is the VCI supplier reputable (ISO

The Cost of Corrosion

Rust can be an ugly sight. But when it comes to the industries that rely on non-corroded metal to run, rust can also lead to some nasty consequences that aren’t always quite so visible: lack of productivity, accidents, and a significant financial loss. Companies are leaching billions of dollars out of their business each year

Corrosion Solutions for Hydrostatic Testing

Hydrostatic testing of pressure vessels such as pipes, heat exchangers, storage tanks, and ship voids is an essential method for quality control of parts after production and during use. This process demonstrates the fitness of the pressurized component for service after production or repair. Hydrostatic testing consists of raising the pressure level above the operating

Enhance Your Part Cleaning With the Use of ZERUST® Products

Part cleaning is an essential step in the manufacturing process, as precision metal parts typically have oils, greases, and other lubricants on the surface after the part is manufactured. These residues can prevent the adhesion of coatings and paints and accelerate corrosion if not properly removed. Manufacturers understand the importance of delivering clean parts in

ZERUST® VCI Film Additives & Custom Options

ZERUST®/EXCOR® (Vapor or Volatile Corrosion Inhibitor) VCI film, poly bags, and tubing are produced using a process known as blown film extrusion. The polyethylene is melted and extruded into sheeting which is then slit, folded, or sealed to the desired size and dimensions. With ZERUST’s vast manufacturing network, we have over 100 extrusion lines in

Does Corrugated Affect Corrosion & What Can You Do About It?

When shipping metal parts in cardboard corrugated boxes, do you allow the unprotected parts to touch the box? If so, then the corrugated may be the source of the corrosion. When cardboard boxes are manufactured, the paper begins as pulp and is then dissolved using nitric acid. In order to neutralize the acid before forming

VCI Poly vs VCI Paper? The Advantages and Disadvantages Explained

Volatile Corrosion Inhibitors (VCIs) have been around since the 1940’s, when a product named Dichan was introduced into market. Dichan consisted of dicyclohexylamine-nitrite, which was described as a vapor phase corrosion inhibitor that had sufficient vapor pressure to release corrosion inhibiting molecules into the surrounding area. Eventually, this chemistry began to be coated onto paper,

VCIs vs Desiccants. How do they Differ?

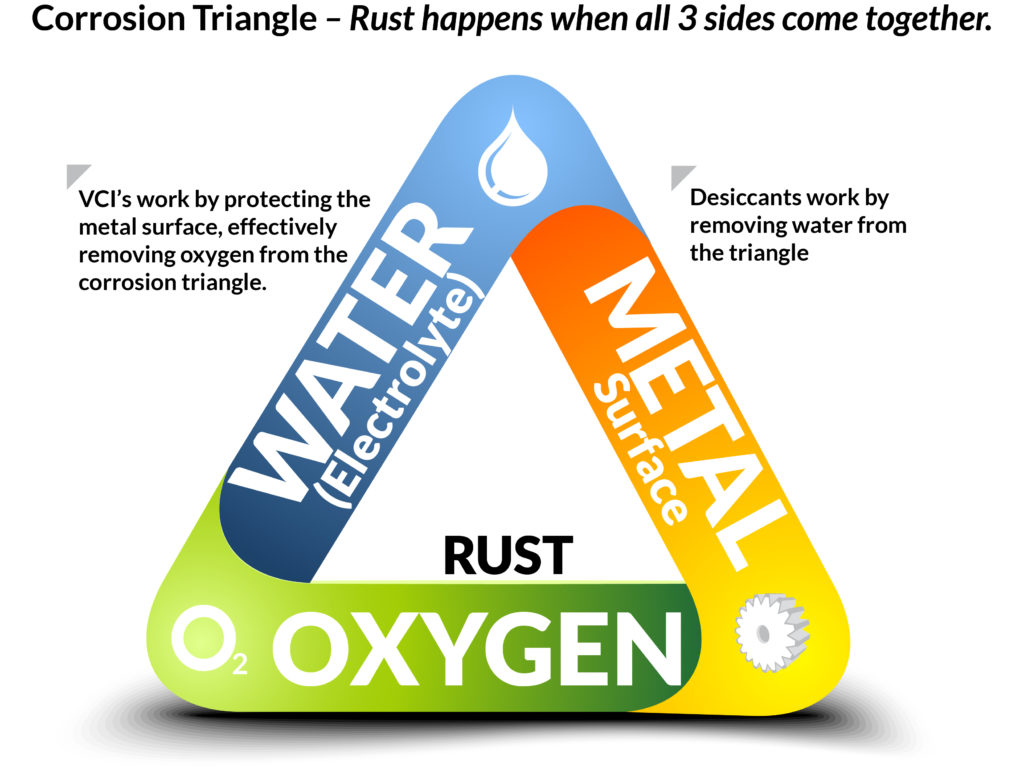

People often confuse VCI (Vapor or Volatile Corrosion Inhibitor) with desiccants, as they are used to control corrosion during shipping and storage. However, the way these chemistries work is much different. Depending on the application, environment, and length of protection, you may get better results with VCI vs. desiccants. Some highly effective packaging systems use